|

Project experience |  |

Filanovsky Offshore Field

| Implementation: |

2012 |

| Project owner: |

LUKOIL Nizhnevolzhskneft LLC |

| Contractor: |

SMT OAO |

| Location: |

Caspian Sea |

| Length: |

350 km |

Two seagoing export pipelines were installed from riser base at the Vladimir Filanovsky field to the landfall, including pipe sections in flood area. The field is located about 50km offshore, in the northern part of the Caspian Sea. The construction area is situated in Russian sector of north-western shallow part of the Caspian sea, 100 km east of Republic of Kalmykia, 40 km northeastward from Astrakhan anchorage area, 20 km east of Maliy Zhemchuzhniy Island.

Water depth in working area differs from 12 m near the riser base to 0 m at the landfall.

Pipeline route crosses Volga-Caspian channel at the point of 175,5 km. Water depth of channel in crosspoint is 4,9 m. Pipeline route also crosses 7 areas determined as “ weak soil”.

Submerged pipes are protected with anticorrosion and concrete coatings, laid at a distance of 30 meters and buried in soil along the whole route.

Nominal sizes of pipes used in the Project

| Outer diameter (mm) | Steel thickness(mm) | Concrete thickness (mm) |

| 711 | 25,4 | 95 |

| 559 | 15,9 | 105 |

| 559 | 20,6 | 105 |

| 406,4 | 17,5 | 70 |

| 406,4 | 17,5 | 45 |

| 406,4 | 12,7 | 80 |

| 660,0 | 25,4 | 85 |

| 323,9 | 11,1 | 65 |

| 323,9 | 11,1 | 55 |

- Technical documentation preparation.

- Receipt, inspection, acceptance and storage of pipes with 3-layered PE coating in accordance with the Project Documentation requirements.

- Supply of the raw materials for concrete coating and corresponded certificates.

- Operating equipment and consumables provision (including corresponded certificates), equipment inspection and testing (including corresponded calibration certificates), coverage oа staff (including corresponded recognition certificates) as it required for coating applying processes execution.

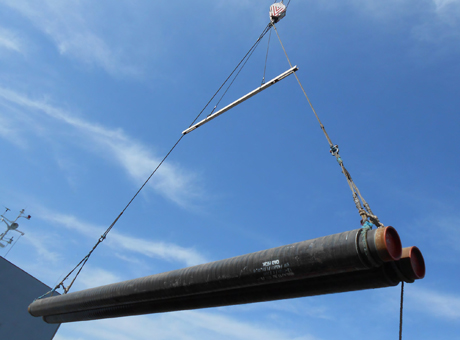

- Concrete weight coating application.

- Installation of anodes on line pipes with concrete coatings and line pipes with anticorrosion coating without concrete weight coating.

- Installation of magnetic markers.

- Concrete coated pipes storage.

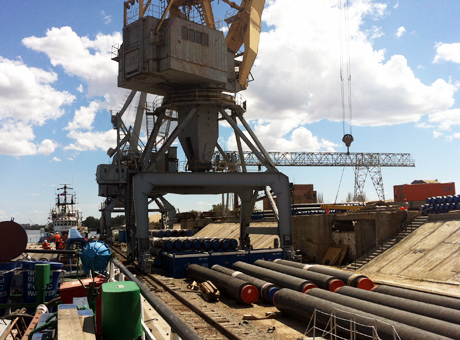

- Transportation, entrucking and embarkment of pipes with concrete coatings according to the corresponded loading operation.

All the Project operations were carried in accordance with the following basic concepts and rules:

· Quality and material-technical supply management in the quantity of Supplier’s works.

- The final inspection by Supplier and Buyer of concrete coated pipes before shipment.

- Pipes record-keeping in accordance with pipe tracking system (PTS) of the Buyer.

- Safety measures for existed and new-built premises as well as personnel and equipment security providing during the operations execution. Adequate safety measures should be provided by Supplier in order to guarantee secure work environment in conformity with the current Russian standards and laws.

- Equipment and personnel qualification should be in conformity with International and Russian normative standards and laws.